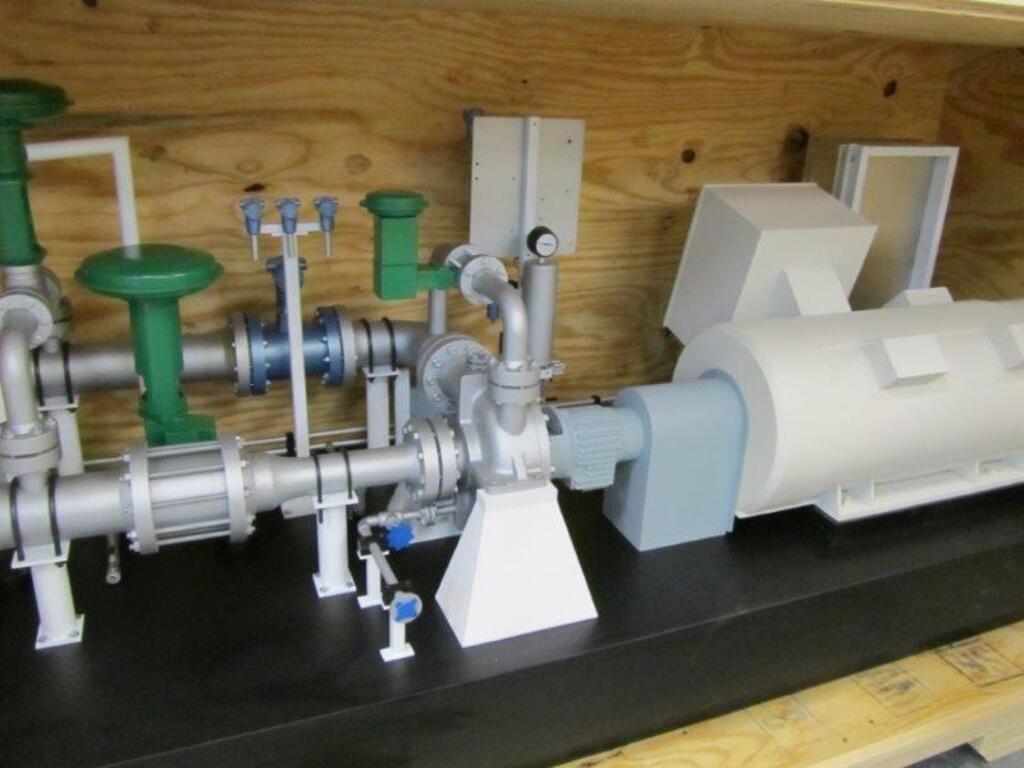

Quick Scale Model Build

Our most recent scale model build went from zero to 100 in 2 weeks. It's not the usual time frame for a large-scale model, but sometimes we are able to accommodate a special client request.

Materials were ordered (some of them overnight delivery) and 3D plans were drawn up on the computer for many of the parts. Then machines were programmed to start fabricating parts. This included our CNC router, CNC mill, laser cutter and 3D printer. A large metal box was cut, bent and welded at a partner shop, right down the street from KiwiMill.

While the machines were spitting out parts, our model makers got to work hand crafting the rest of the components, using acrylic and modeling board. A base was hand-built out of plywood and laminated black, as well as a shipping crate constructed.

As parts came off the mill, laser, router and printer, they needed to be finished, primed and painted. On the final day these parts were assembled into a scale model of a skid machine. The model was attached to the base, crated and out the door on day 10. Phew!